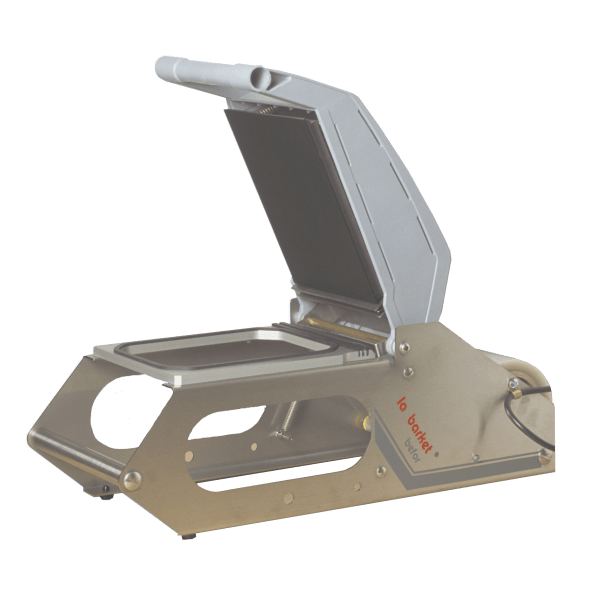

General characteristics

Vacuum packaging machine in table-top design

Acid-resistant cover

An acid-resistant deep-drawn vacuum chamber ensures optimal hygiene

Transparent lid (except BOXER 42 XL Bi-active)

Cordless welding heads that can be easily removed from the vacuum chamber

The depth of the vacuum chamber can be adjusted with space-filling trays

Packaging functions

Vacuum: optimum final vacuum 99.99% (0.1Mbar)

Gas injection: the injected gas protects the product from mechanical damage and significantly increases its shelf life

Soft-air: controlled ventilation, ie slow vacuuming and air release, which protects soft products from compression

Welding

Bi-active sealing 1 x 5 mm flat welding wire in the vacuum chamber as well as on the top. This also makes it possible to weld vacuum pouches thicker than 200 microns or aluminum triplex pouches. (BOXER 42 XL Bi-active model only)

Control functions

Digital control: time control / automatic programming / 10 program options

Sensor control: by adjusting the vacuum and gas injection pressure an accurate and consistent quality packaging can be ensured / automatic programming / 10 program options / plus vacuum time

Other functions

The program can be stopped partially or completely at any time using the STOP button

There is a unique program in the control to maintain the vacuum pump / operating hour counter / service alarm program / standby mode, etc.

Options

Special pad for liquid packaging

Connector for vacuuming the external tray

Service package for maintenance

Special control options for individual designs

Technical details

Chamber size (l/w/h): 410 x 520 x 180mm

Machine size (l/w/h): 528 x 698 x 440mm

Welding head length: 2x 410 mm

Vacuum pump performance: 021 m3/h

Cycle time: 20-40 sec.

Machine weight: 73 kg

Performance: 0.75-1kW

230V-1-50 Hz

You can watch a video on using the machine HERE.